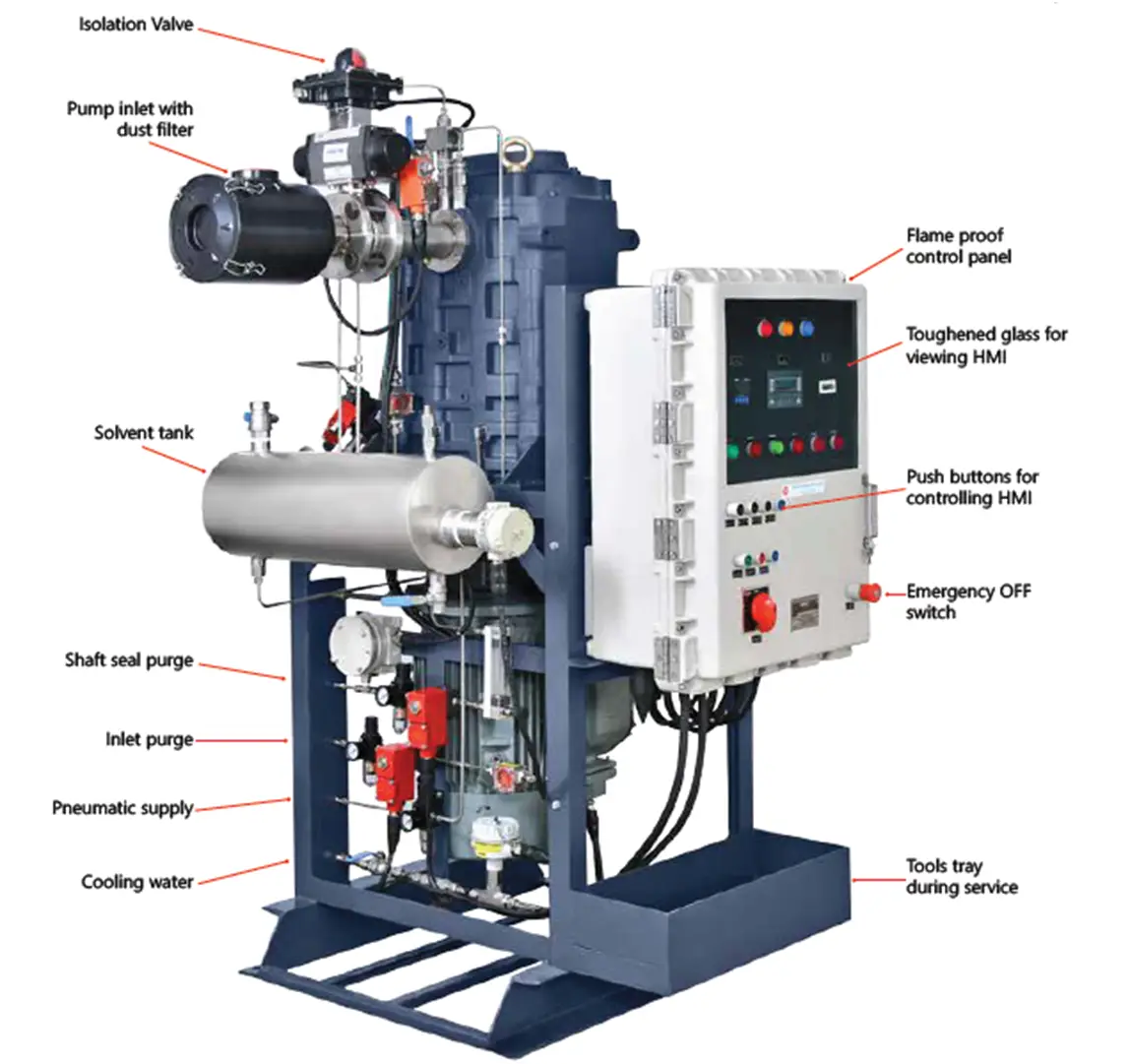

Dry Vacuum System

Salient Features :

- Vertical Design

- Uncoated Pump

- Without Mechanical Seal

- Maintenance at Site

- Lower Ownership Cost

Performance Data:

| Particulars | Unit | DP300/DP300S |

|---|---|---|

| Description/Frequency/Phase | Hz | 50 |

| Orientation | - | Vertical |

| No. of stages | - | 4 |

| Construction | - | 1root+3claw |

| Maximum pumping speed | m³/h | 300 |

| Ultimate pressure (total pressure) | mbar | 0.05 |

| Motor power | kW | 11 |

| Weight | kg | 565 |

| Noise level** | dB(A) | 78 |

| Inlet connection | - | ISO63 |

| Exhaust connection | - | KF50 |

| Gearbox oil capacity | L | 3.5 |

| Recommended oil (supplied) | - | ISOVG 150 |

| Cooling system type | - | Direct water-cooling |

| Cooling-water flow | l/min | 5 to 10 |

| Supply temperature range | deg. C | 5 to 35 |

| Cooling-water supply pressure | bar G | 2 to 10 |

| Shaft-seals air/nitrogen purge | - | Yes |

| Pressure relief valve | - | Yes |

| Overall dimensions (Length × Width × Height) | mm | 850×730×1614 |

- Capacity @ 1torr :300m3/hr

- Capacity @0.1 torr : 100m3/hr

- Ultimate Vacuum- Pump with booster : 0.005 mbar

- Pump with Booster : 1000 m3/hr @ 0.1 torr

- Pump with 2 Boosters : 2000 m3/hr @ 0.1 torr

Material Of Construction:

- Stators: Spheroidal Graphite Iron SG 450-10 IS:1865 (Ductile Iron / Nodular Iron)

- Rotors - Claw and Lobe: Spheroidal Graphite Iron SG 450-10 IS:1865 (Ductile Iron / Nodular Iron)

- Shafts: Medium Carbon Steel (45C8)

- Shaft Seal: PTFE Lip Seal

- O-rings: FKM (Viton)

Industries Served :

- Chemical

- Pharmaceuticals

- Food

- Medical

- Electrical and Power

Typical Applications:

- Distillation

- Drying

- Filtration

- Solvent Recovery

- Centralizied Vacuum System - Pharmaceuticals Laboratories

- Freeze Drying

- Short Path Distillation

- Steam Sterillization

Dry Vacuum System